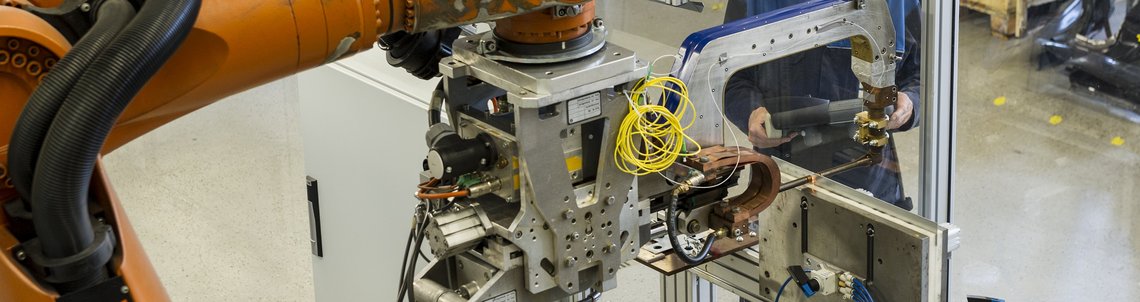

Pressure welding

Pressure welding techniques use superimposed forces for mass production as used in automotive and railway vehicle construction, steel composite applications and the electrical industry. Research needs arise from new and innovative materials and manufacturing concepts from development to deployment.

Research projectsd

Current research projects

- Sequential compacting

- evelopment of a pressure welding method for joining copper and aluminium using controlled eutectic formation

Completed research projects

|  | |

|  | |

| ||

| ||

|  | |

|

Services

- Research projects

- Industrial research

- Technology and process development

- Technological consultation

Process variations

Resistance welding

- Spot welding

- Projection welding

- Roller-seam welding

- Pressure butt welding

- Seam-buildup welding

- Resistance soldering

Stud welding

- Capacitor-discharge welding

- Drawn-arc welding

- Short-cycle drawn-arc welding

- Stud welding with magnetically impelled arc

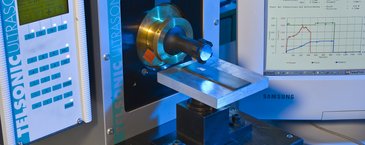

Ultrasonic welding

- Ultrasonic spot welding

- Ultrasonic seam welding

Technical equipment

Contact

Phone +49 345 5246-500

Fax +49 345 5246-403

email fue@slv-halle.de